https://youtu.be/mhMxYTkrwsg

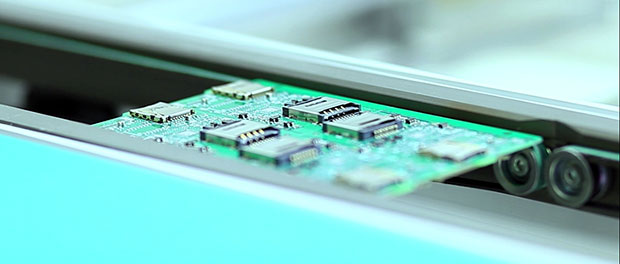

VILNIUS, Lithuania, 2017-Aug-04 — /EPR ELECTRONICS NEWS/ — Promwad Electronics Design House has partnered with leading technological fabless companies in China and Southeast Asia to offer its clients cost-effective electronics product development from the center of Europe and to manufacture any batch size of new devices with priority tech support.

Promwad was one of only a few design houses in the EMEA region authorized by Allwinner, one of the leading Chinese chip manufacturers. Promwad’s engineers design electronics based upon Allwinner components and provide tech support during the entire life cycle of the designed devices:

- tablet PCs, multimedia and portable devices based on Allwinner SoC A series;

- TV set-top boxes with OTT and IPTV based on Allwinner SoC H series;

- dash cameras, video cameras and action cameras based on Allwinner SoC V series;

- onboard multimedia systems for vehicles based on Allwinner SoC T series.

Allwinner was founded ten years ago; its headquarters are based in Zhuhai, Guangdong, China. In 2013 and 2014 this chip vendor was the world’s largest supplier of application processors for Android tablets.

Also Promwad became an official partner of Telink, Shanghai, and has significantly expanded its expertise in the fields of Bluetooth and BLE. This chip vendor specializes in Bluetooth and Zigbee for IoT and wearable electronics, remote controls, smart lighting and smart toys.

The engineers of Promwad have a lot of experience with the most popular chipsets of other vendors: TI CC265x, Silabs EFR32 Blue Gecko, Nordic nRF, Qualcomm/CSR10xx, and Dialog DA1458x. And now Telink TLSR826x BLE SoC has been added to this list; this system on chip has low power consumption, supports Zigbee, 6LoWPAN/Thread, and HomeKit.

Promwad maintains cooperation with the company Realtek from Taiwan and uses its chips to design network equipment from CPE – routers, gateways, WiFi hotspots to operators-side telecom equipment such as unmanaged and managed switches.

“Today the center of the semiconductor industry’s innovations and manufacture is shifting to Asia. Traditional chip vendors from the USA and Europe face growing competition from this region. Our customers demand functional and cost effective solutions to be designed at closer location such as Belarus or Lithuania and manufactured in Asia, that’s why establishing close links with Asian chip makers is a natural step for us,†says Ivan Kuten, the Business Developer of Promwad. “Namely by using such cooperation we cover our most growing capabilities in tablets, consumer gadgets, STB, CPE and multimedia devices. Now our customers in the EU and North America can create new hi-tech devices with controlled costs, tech support in English and manufacturing facilities in Europe or Asia.â€

Contact-Details: Olga Potonya

olga.potonya@promwad.com

+370 (5) 214 12 44 ex.227

Via EPR Network

More Electronics press releases