CAMBRIDGE, 8-Jan-2025 — /EuropaWire/ — While electronics have seen exponential advances in speed, size, and capability, one element has remained unchanged: the form factor. Despite innovations, the core of most devices still consists of components mounted on circuit boards packaged within a box. As the demand for faster and more compact devices rises, a unique opportunity has emerged for designers to redefine the human-machine interface—making it 3D, flexible, or stretchable.

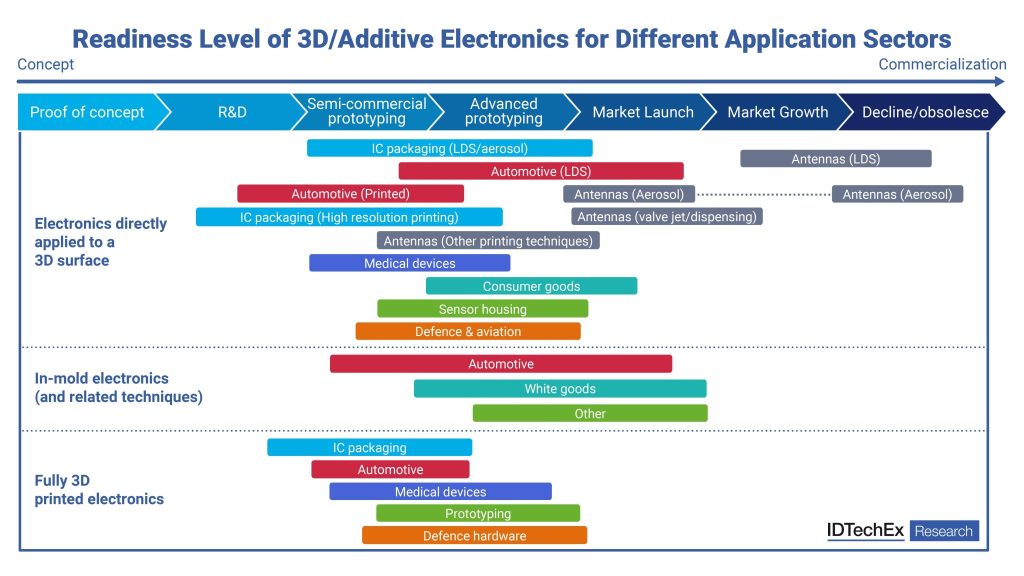

A $4.3 billion opportunity by 2034 awaits in the 3D electronics market. Despite being an “embryonic” technology, 3D electronics—such as 3D-printed antennas and capacitive touch switches—are set to revolutionize the industry. According to the IDTechEx report “3D Electronics/Additive Electronics 2024-2034: Technologies, Players, and Markets,” the market for 3D electronics will reach $4.3 billion in 2034.

The report delves into a variety of manufacturing technologies that are being developed to create 3D electronics. One such technology, In-Mold Electronics (IME), is a particularly promising example. IME uses a thermoforming process where conductive traces are printed and components are mounted before the substrate is shaped into a 3D component.

IME is an evolution of In-Mold Decorating (IMD), a well-established manufacturing technique in which plastic is thermoformed with a decorative coating and then injection molded into 3D components. The new IME process leverages existing knowledge and equipment from IMD, although it does come with a learning curve.

Currently, IME is still a few years away from widespread adoption, but the groundwork for its commercialization is well underway. The IDTechEx report “In-Mold Electronics 2025-2035: Forecasts, Technologies, Markets” notes that the manufacturing ecosystem for IME is largely established, though only a handful of commercial product examples (like smoke detectors and smart locks) have been disclosed by manufacturers. The real growth, however, is expected in the automotive sector, with IME anticipated to replace mechanical switches and other traditional components in automotive applications.

IME’s appeal to the automotive industry lies in its potential to reduce the physical volume and weight of components. For instance, IME’s embedded lighting solutions allow for thinner parts (down to just 8mm) compared to conventional alternatives (28mm). Furthermore, unlike traditional LED lighting panels, IME components do not require a bezel, as LEDs can be positioned closer to the light source, reducing the LED count and power consumption while still meeting application requirements.

As of 2025, IME is being explored for a variety of automotive applications, with full adoption expected around 2027-2028. According to IDTechEx’s forecast, the IME market is expected to be worth $974 million by 2035.

Product designers have yet to fully recognize the potential of 3D electronics as a point of differentiation. Traditionally, competition has focused on the internal components of devices, but the design of the external form factor—how the electronics interact with the physical world—offers an untapped opportunity. For designers, this is an open invitation to lead in the emerging 3D electronics space.

For more information on 3D electronics and to access downloadable sample pages of the full IDTechEx report, visit www.IDTechEx.com/3DElec.

To explore IDTechEx’s full portfolio of 3D printing market research, visit www.IDTechEx.com/Research/3D.

SOURCE: EuropaWire